The 5-axis CUT 500 cnc bridge saw is the top-of-the-line Helios Automazioni; ideal for marble, granite, porcelain, and sintered materials. Cut 500 has been designed for superior performance, reliability, and versatility. Choose this machine to achieve exceptional results in your stone and porcelain fabrication.

• Extreme precise cuts of slabs with different size and thickness.

• Fabrication of bath and kitchen countertops, coverings and decorative walls.

• Artistic works on stone and porcelain materials.

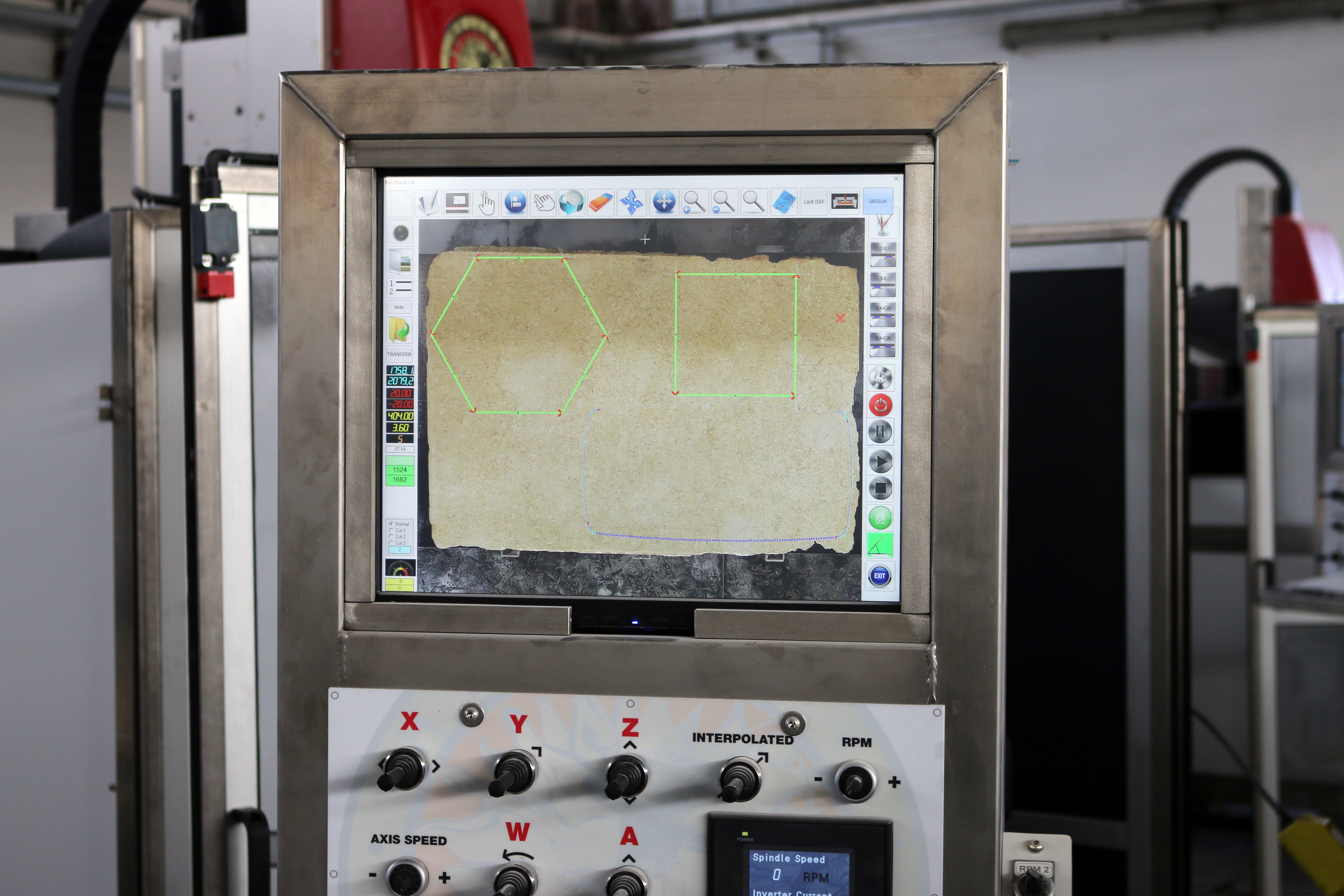

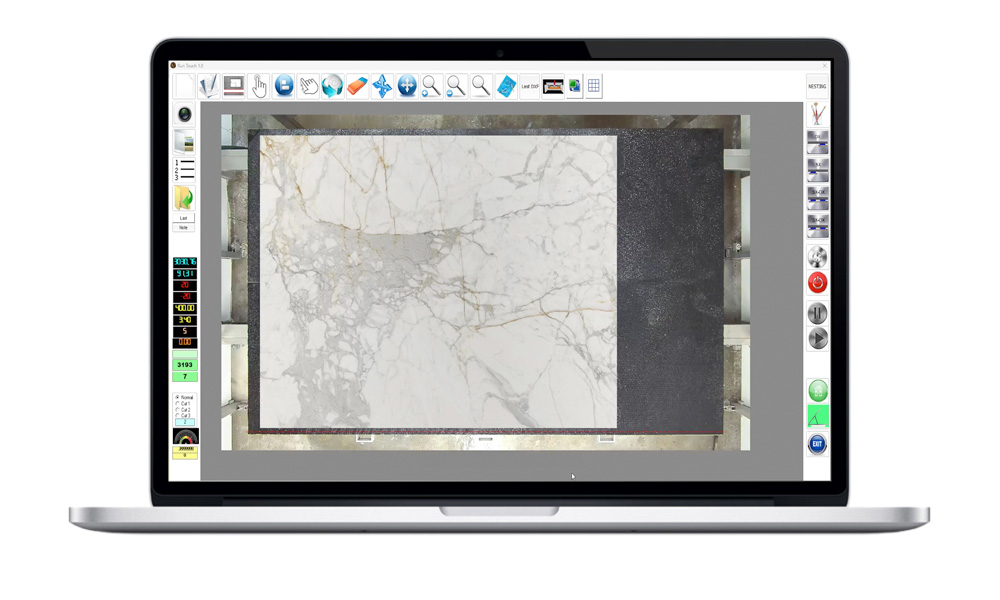

The Run-Touch software has been developed by Helios Automazioni to optimize the performances of the bridge saws and of the polishing machines. The main purpose of the Run-Touch software is to simplify and improve the daily operations of the stone fabricators, offering an intuitive and productive experience. The Run-Touch software represents a tailor-made solution for the daily routine of the stone fabricator, it improves the job quality and the management of the orders. With a user-friendly approach and particular attention to the needs of this specific industry, the Run-Touch software makes the work easy and increases the efficiency of the overall process.

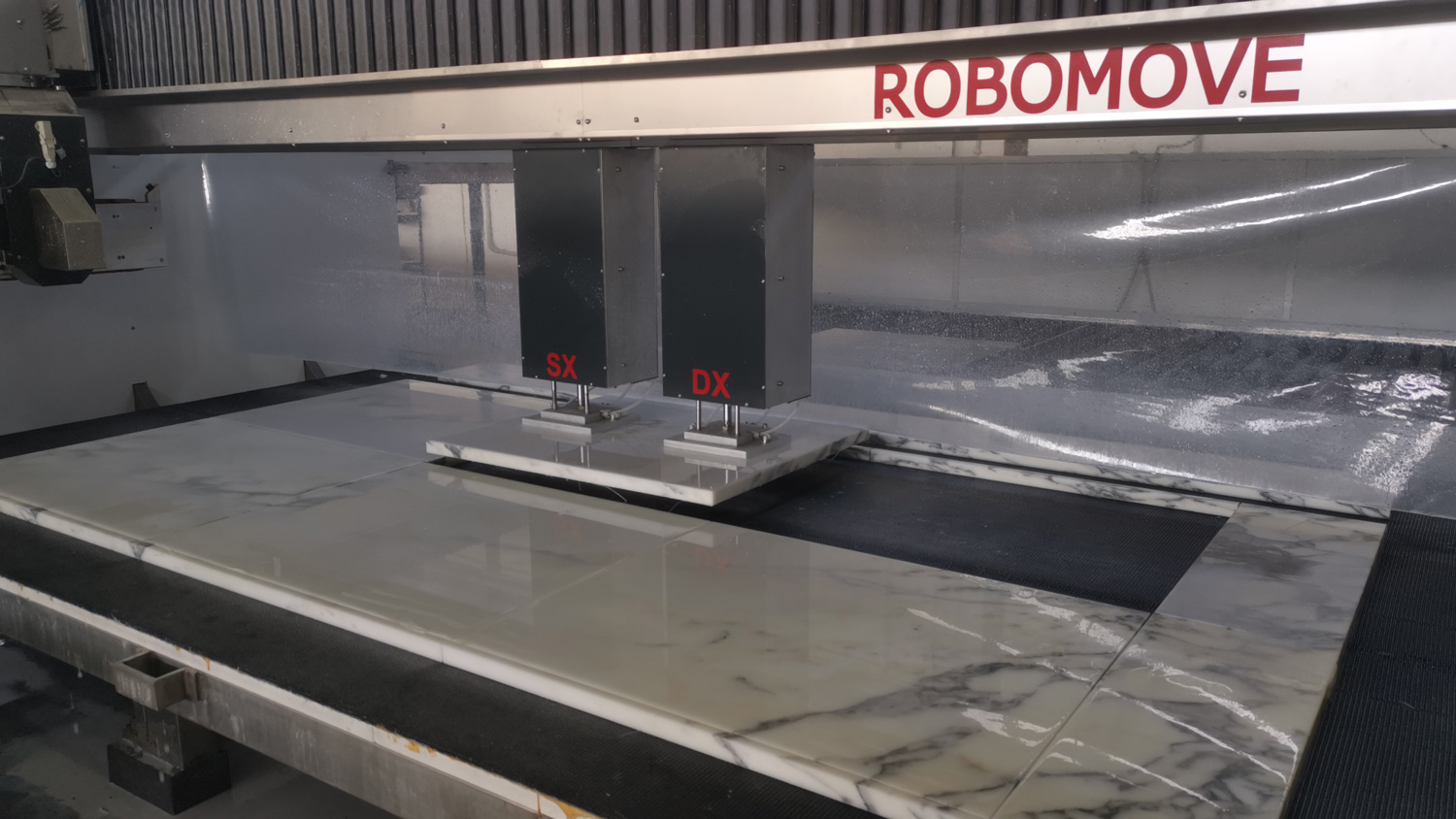

| Stainless steel structure | The sturdy stainless-steel structure ensures stability and resistance to corrosion, preserving its qualities and performances over the time. |

|---|---|

| Stainless-steel working table | The stainless-steel table ensures a stable, durable and perfect surface to work all materials on. |

| Big working area | The machine can work different size pieces on 151,57 in x 94,48 in (Cut 500 XL). |

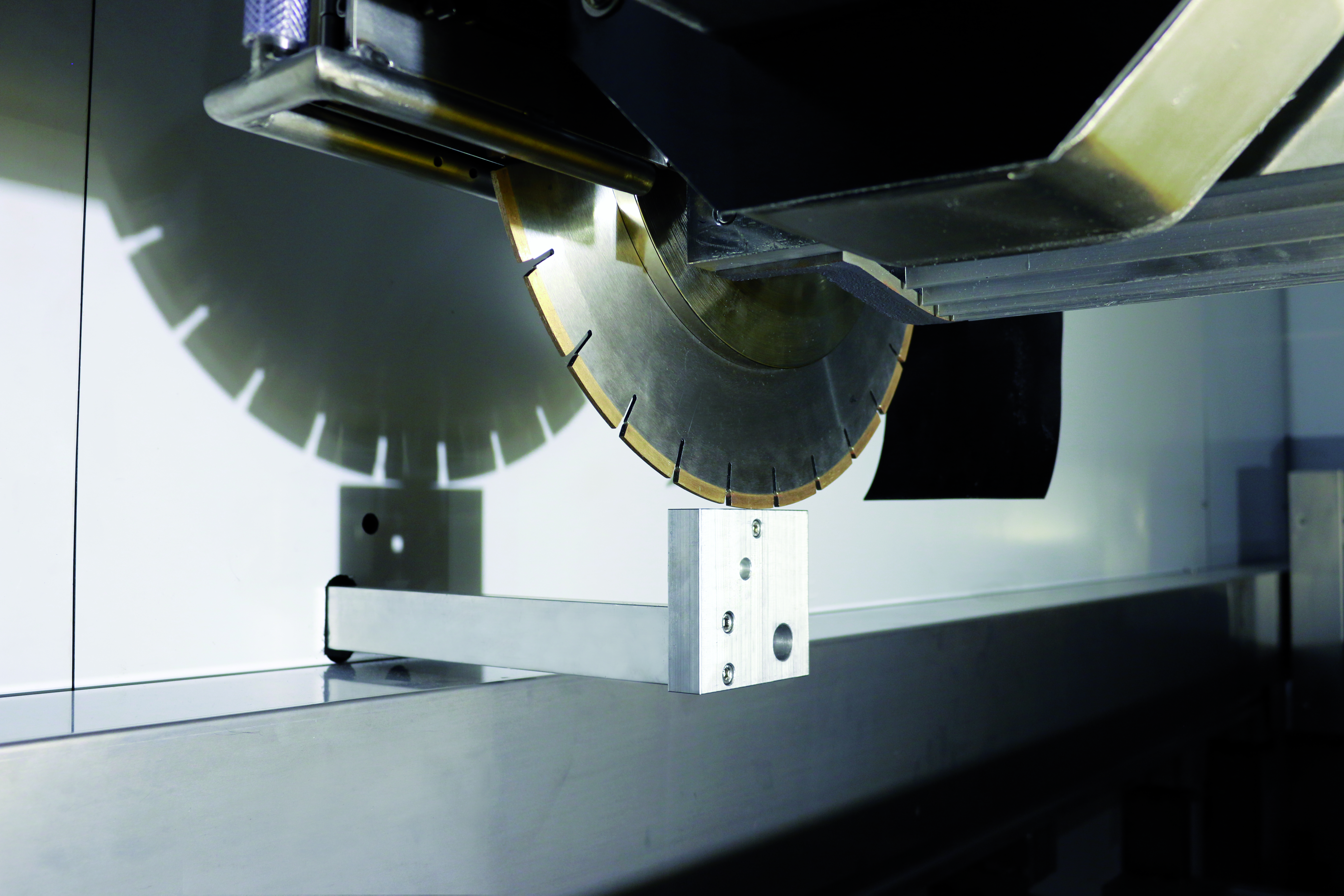

| Z-Axis stroke | 18.89 in z-axis stroke allows 3D works with extremely accurate details. |

| Cutting versatility | Cut 500 works with discs on marble, granite, quartz and ceramics, as well as with tools thanks to the second electro-spindle option. |

| Brushless motors | The advanced electronics of the brushless motors ensure stable and reliable performances. |

| Precision mechanics | Thanks to the recirculating ball screws and to the harmonic-drive gearboxes, the movements of the machine are fluid and precise. |

| Run-Touch software | The intuitive Run-Touch software makes the use of the machine simple and programming accessible even to less skilled operators. |

| Full warranty | The machine is covered by a 2-year full warranty, which makes you work carefree and safe. |

| Cut 500 | Cut 500 XL | |

|---|---|---|

| Overall dimensions | 212,59 x 151,57 x H114,96in | 232,28 x 151,57 x H114,96 in |

| Working area | X131,88 - Y94,48 - Z13,38 in | X151,57 - Y94,48 - Z13,38 in |

| W axis rotation | 0° ÷ 360° | 0° ÷ 360° |

| A axis rotation | 45° ÷ 90° (optional 0° ÷ 90°) | 45° ÷ 90° (optional 0° ÷ 90°) |

| Disc motor power | 11,8 kW | 11,8 kW |

| Disc motor rotation speed | 0 ÷ 4500 rpm | 0 ÷ 4500 rpm |

| Installed power | 18 kW | 18 kW |

| Power supply | 400 V (3P + N + GND) 50/60 Hz | 400 V (3P + N + GND) 50/60 Hz |

| Max. speed axis X | 1181,10 in/min | 1181,10 in/min |

| Max. speed axis Y | 787,40 in/min | 787,40 in/min |

| Max. speed axis Z | 393,70 in/min | 393,70 in/min |

| Table dimensions | X129,92 - Y78,74 in | X129,92 - Y78,74 in |

| Disk diameter | min. 13,78 in - max. 19,68 in | min. 13,78 in - max. 19,68 in |

| Max. cutting depth | 5,12 in (19,68 in disk) | 5,12 in (19,68 in disk) |

| Disk hole diameter | 1,96 in | 1,96 in |