Our bridge saw doesn't need any manual intervention when processing a slab for a countertop, that's great for your wellness at work. The user-friendly software and some accessories offer many strategies to work the less as possible at the maximum capacity of production.

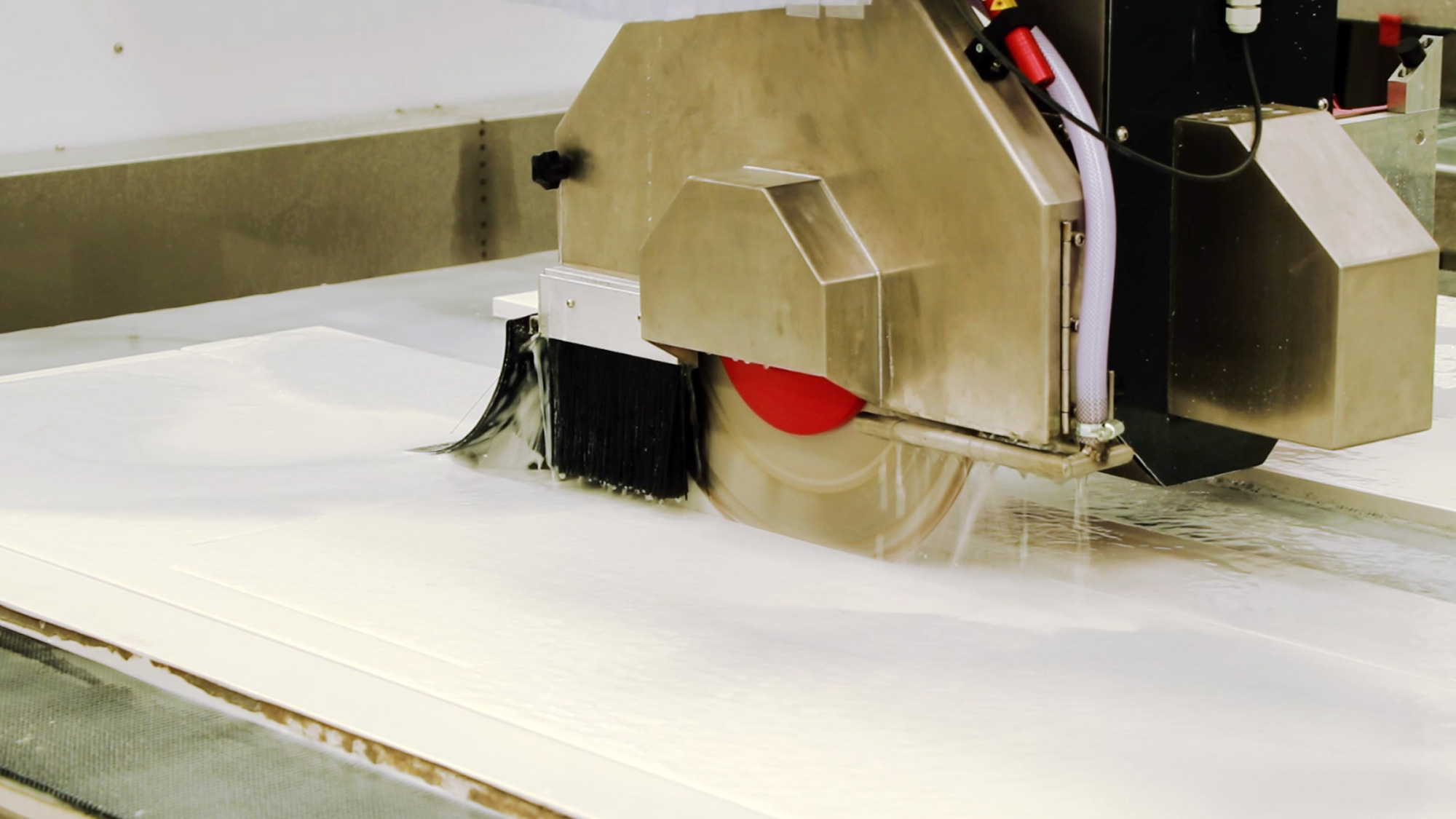

Helios Cut 500 is a fast and performing 5 interpolated axes bridge saw. It has been developed for high precision cutting processes on ceramics, quartz, compact surfaces as well as marbles and granites. The exclusive characteristic is the stainless steel monolithic structure, which guarantees a total endurance against corrosion and a remarkable duration over the time. The bridge saw can have both manual and total automated functions thanks to the advanced levels of the software, which allow to process easily a lot of jobs such as multiple linear cuts, perpendicular linear cuts, mitering, cut of kitchen/bath tops, calibration, decorative walls, shaping, inclined cuts, net and clean cuts, roughing, scraping, fan-shaped stairs, template reading, and much more. The integrated Helios Run-touch software is user-friendly and intuitive, it can be combined to Helios Photoscan, which is the slabs scanner, as well as measuring system and template reader. Together they can start the cutting process just a click away.

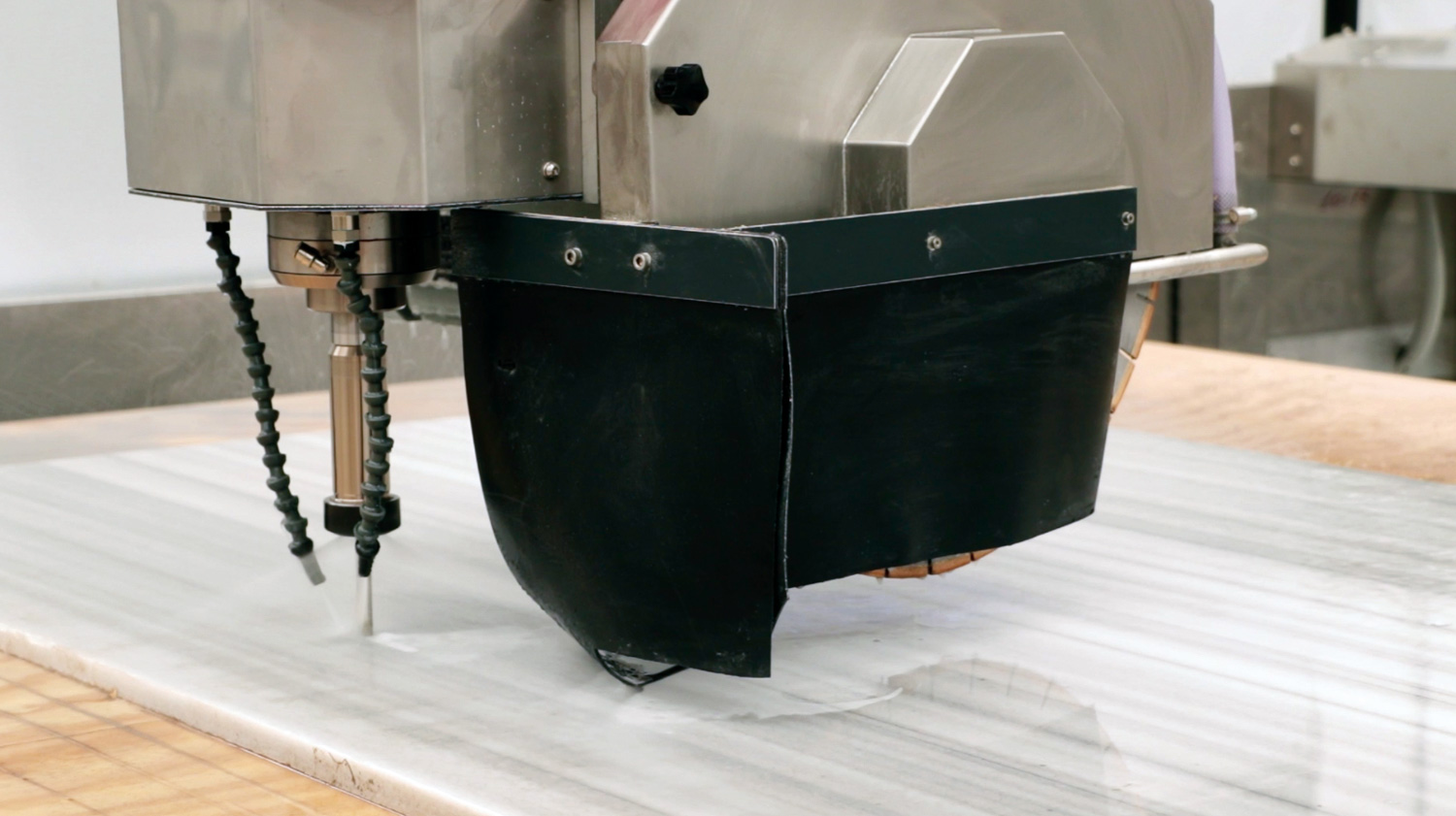

Moreover Helios Cut 500, equipped with a second spindle, can boast a superior accuracy and lower costs of management compared to the other combined saws. The whole process is set up before starting the machine, easily and fast with the integrated Run-touch software. The carving solution on the 5-axis bridge saw Helios Cut 500 is the great goal to make stone fabrication easier and more efficient. Besides all the 5-axis cutting functions such as multiple linear cuts, perpendicular linear cuts, mitering, cut of kitchen/bath tops, calibration, decorative walls, shaping, inclined cuts, net and clean cuts, roughing, scraping, fan-shaped stairs, and much more; the second head for carving jobs offers effective solutions in all the processes, where it is needed, such as the sinks cut out.