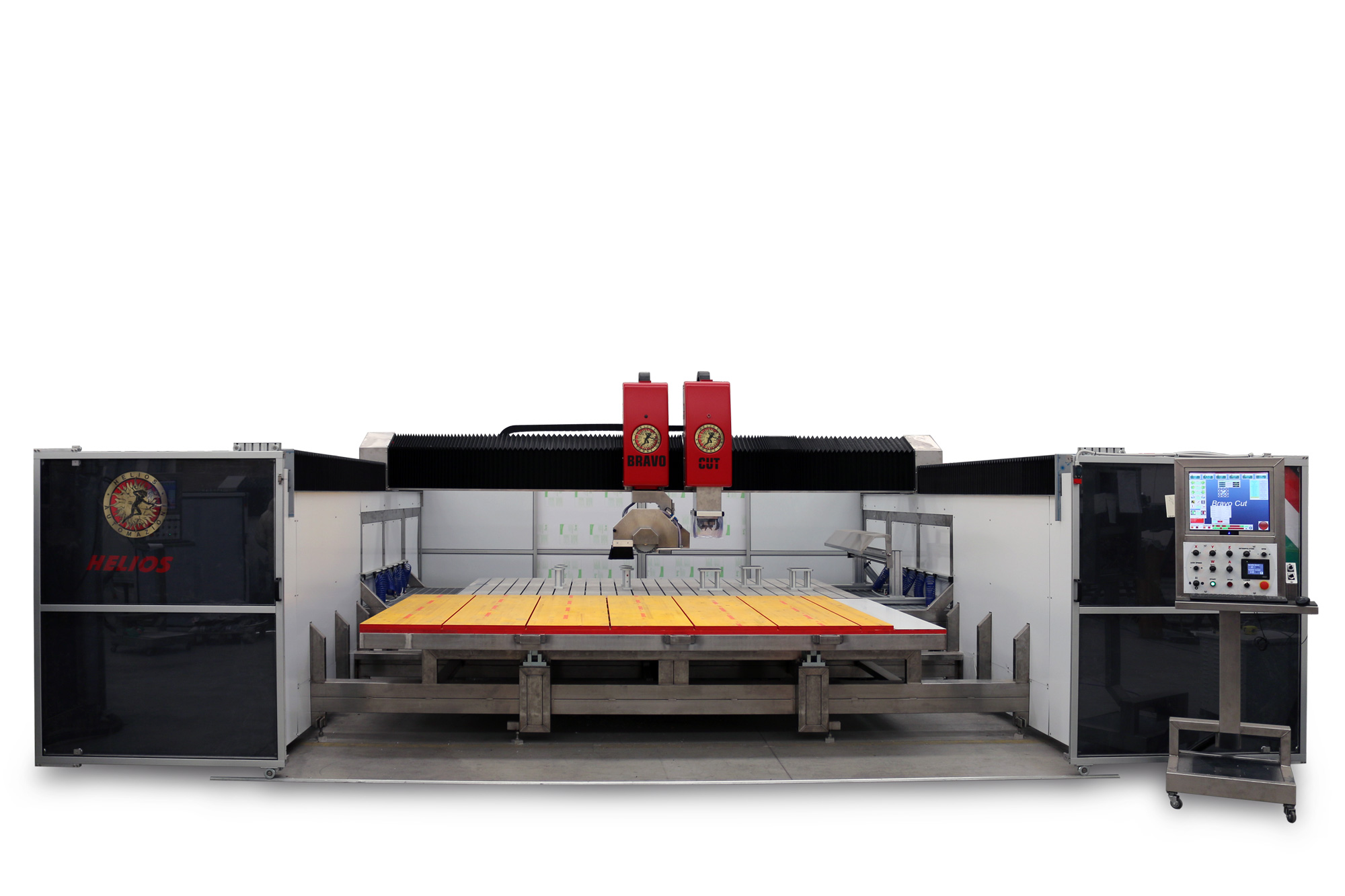

Helios BravoCut has two spindles on the same bridge. One manages all the cutting functions and the other all the processes of a machining center. Thanks to the stainless steel monolithic structure, Helios BravoCut preserves its value and quality over the time. The integrated sotware is under Windows: the Galaxy Stone manages all the functions of the machining center and the Run- Touch all the cutting processes. The 3-axis operating head has been designed to fabricate bathroom and kitchen tops with edge profiling; inlaid / relief / engraved lettering using all certified Windows fonts, bas-reliefs, frames, 3D floors, and much more; while the 5-axis head for all cutting processes.

| BravoCut | BravoCut Plus | |

|---|---|---|

| Overall dimensions | 232,28 x 228,35 x H98,42 in | 232,28 x 228,35 x H98,42 in |

| Working area | X132,67 - Y118,11 - Z12,79 in | X132,67 - Y118,11 - Z12,79 in |

| W axis rotation | 0° ÷ 360° (optional continuous rotation) | 0° ÷ 360° (optional continuous rotation) |

| A axis rotation | 45° ÷ 90° (optional 0° ÷ 90°) | 45° ÷ 90° (optional 0° ÷ 90°) |

| Power supply | 400 V (3P+N+GND) 50/60 Hz | 400 V (3P+N+GND) 50/60 Hz |

| Installed power | 22 kW | 25 kW |

| Spindle rotation speed | 0 ÷ 9000 rpm(2) - 0 ÷ 4500(1) | 0 ÷ 9000 rpm(2) - 0 ÷ 4500(1) |

| Spindle power | 3,7 kW(2) - 11,8 kW(1) | 5 kW(2) - 11,8 kW(1) |

| Tool magazine | - | 10 positions |

| Max. velocità asse X | 1181,10 in/min | 1181,10 in/min |

| Max. velocità asse Y | 787,40 in/min | 787,40 in/min |

| Max. velocità asse Z | 393,70 in/min | 393,70 in/min |

| Disk diameter | min. 13,78 in - max. 19,68 in | min. 13,78 in - max. 19,68 in |