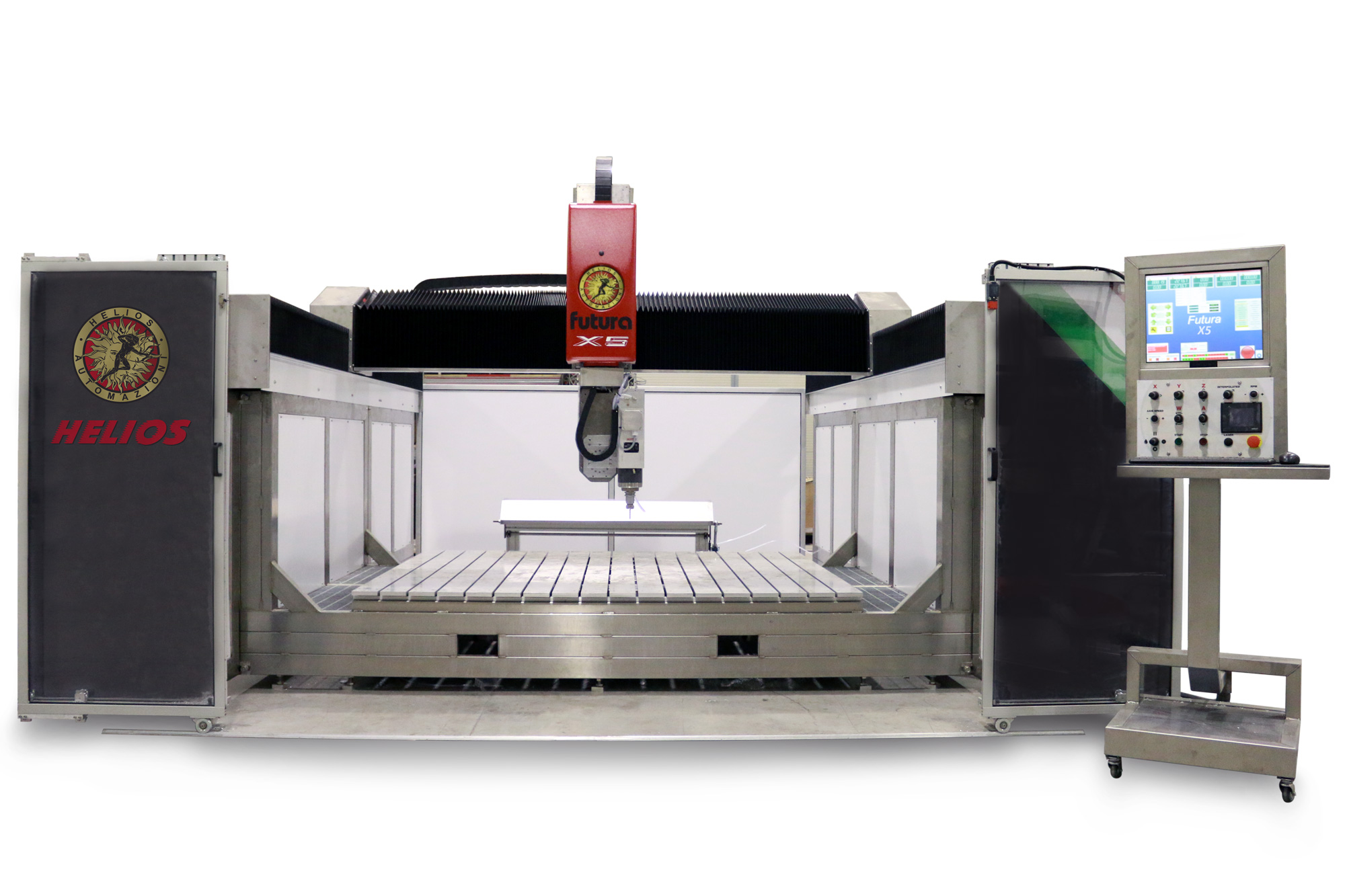

FUTURA X5 is a great 5-axis machining center. It has been designed for all the functions of shaped cutting, profiling, polishing, engraving, and carving. The use of recirculating ball screws, zero backlash gears, and Harmonic Drives makes the machine’s movements extremely precise, thus producing highly detailed works. These components, minimizing the friction between their parts, are also very resistant to intense use.

• Kitchen countertops and bathroom tops: cutting, profiling, and detailed processing for tailor-made countertops fabrication

• Tombstone fabrication: memorial building and tombstone fabrication with edge profiling and polishing with accurate details

• Shower trays and sinks: precise and refined fabrication of shower trays, sinks, and similar products

•Tailored interior design: fabrication of decorative elements, design details and customized components on stone and many other materials.

| Stainless steel structure | Thanks to the monolithic stainless steel structure, Helios Futura X5 is sturdy machine, that preserve it's quality over the time |

|---|---|

| Precision and reliability | The use of recirculating ball screws makes the machine’s movements extremely precise, thus producing highly detailed works |

| Aluminium rectified table | The aluminium rectified table guarantees the integrity of the table and a total resistance to the processes stress and to corrosion. The calibration, performed directly by the machining center, ensures the perfect flatness of the support surface |

| Automatic tool change and tools magazine | Helios Futura X5 with automatic tool changer manages all the machining center functions. The magazine has got 9 positions that ensure the maximum versatility in the tools choice |

| Galaxy Stone software | The Galaxy Stone software manages the 5-axis machining center Helios Futura X5 and allows to produce automatically bath and kitchen tops with profiling, inlaid / relief / engraved lettering using all certified Windows fonts, bas-reliefs, frames, 3D floors, and much more |

| Command consolle | The command consolle include everything needed to control the machines: the LCD display, the mouse, the keyboard, the command buttons, and the joystick. |

| Futura X5 | |

|---|---|

| Overall dimensions | 153,54 x 185,03 x H110,23 in |

| Axes stroke | X92,52 in - Y78,74 in - Z18,89 in - W0° ÷ 360° |

| Power supply | 400 V (3P+N+GND) 50/60 Hz |

| Installed power | 9 Kw /16 Kw |

| Spindle rotation speed | 0 ÷ 9.000 rpm |

| Tool holder | ISO BT 40 |

| Tool change | Automatic |

| Max. speed axes | 590,55 in/min |

| Electro-spindle power | 5,5 Kw |

| Template reader | Explorer laser 3D for model detecting |

| Inclined draining boards device | Explorer 3000 - 3D model digitizer |

| Flatness control device | Lathe |