Helios Kompact is the 3-axis CNC machining center suitable for every workshop looking for versatility and precision. Thanks to the sturdy structure, recirculating ball screws, and linear guides, it is the best product for the sacred art and for the interior design sector. The exclusive Galaxy Stone software, running under Windows and developed by Helios Automazioni engineers, makes the machinings very easy and fast, thus automatizing the entire process. Helios Kompact has been developed paying specific attention to the operator's safety at work. Moreover, thanks to the tool refrigeration through water, it is possible to have an abatement of the dust emission in the air.

| Monolithic stainless steel structure | Thanks to the monolithic stainless steel coated structure, Helios Kompact is a sturdy machine, that preserves its quality over the time; |

|---|---|

| Precision and reliability | The use of recirculating ball screws makes the machine’s movements extremely precise, thus producing highly detailed works; |

| High-quality electronics | The electronic components of Helios Kompact have got CE certifications, important quality indicators; |

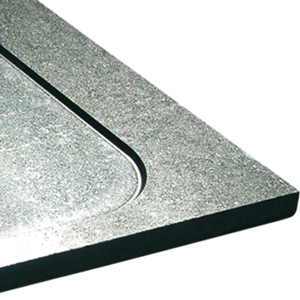

| Aluminium rectified table | The aluminium rectified table guarantees the integrity of the table and a total resistance to the processes stress and to corrosion. The calibration, performed directly by the machining center, ensures the perfect flatness of the support surface; |

| Automatic tool change and tools magazine | Helios Kompact with automatic tool change manages all the machining center functions. The magazine, containing 12 positions, ensures the maximum versatility in the tools choice. Its capacity can be modified according to specific needs; |

| Security doors | The front security doors have got a manual sliding system with automatic machine check sensor in case of opening; |

| Galaxy Stone software | The Galaxy Stone software manages the 3-axis machining center Helios Kompact and allows to produce automatically bath and kitchen tops with profiling, inlaid / relief / engraved lettering using all certified Windows fonts, bas-reliefs, frames, 3D floors, and much more; |

| Sacred art package | The sacred art package includes all the applications necessary to process the typical works of the sacred art: inlaid / relief / engraved lettering, sculptural fonts, bas-relief, frames, drilling patterns for bronze letters, 3D floors, all certified Windows fonts, sacred images, and much more; |

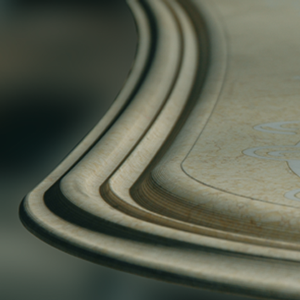

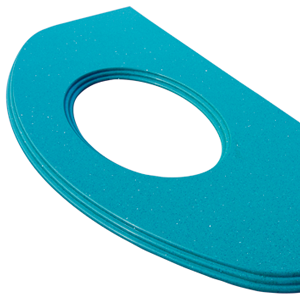

| Tops and drain boards equipment | This customization allows to process kitchen and bathroom tops very quickly with an excellent product finishing, thanks also to the integrated section of the software; |

| Command consolle | The command consolle includes everything needed to control the machine: the touch screen display, the mouse, the keyboard, the command buttons, and the joystick. |

| Kompact | Kompact Plus | |

|---|---|---|

| Overall dimensions | X143,7 - Y110,24 - Z98,42 in | X143,7 - Y110,24 - Z106,3 in |

| Working area | X98,42 - Y62,99 - Z16,53 in | X98,42 - Y62,99 - Z19,09 in |

| Power supply | 400 V (3P+N+GND) 50/60 Hz | 400 V (3P+N+GND) 50/60 Hz |

| Installed power | 16 kW | 16 kW |

| Spindle rotation speed | 0 - 9000 RPM | 0 - 9000 RPM |

| Compressed air | Min. 7 bar | Min. 7 bar |

| Tool holder | ISO BT 40 | ISO BT 40 |

| Max axis speed | 1377,95 in/min | 1377,95 in/min |

| Bridge passing | 17,91 in | 25,79 in |

| Water consumption | 40 L/min | 40 L/min |

| Net weight | 7716,18 lb | 8157,10 lb |

| Lathe | Stainless steel structure for the lathe positioning behind the working table |

| Tools resetting and flatness control device | Laser pointer for the suction cups setup |

| Explorer laser 3d for model detecting | Template reader |

| Y extra travel | Inclined draining boards device |

| 4th axis for 360° rotation in continuous | Gearbox option for straight cutting with disk and for columns’ grinding |

| Gearbox option for frontal sculptures | Gearbox option for cutting with convex disk |