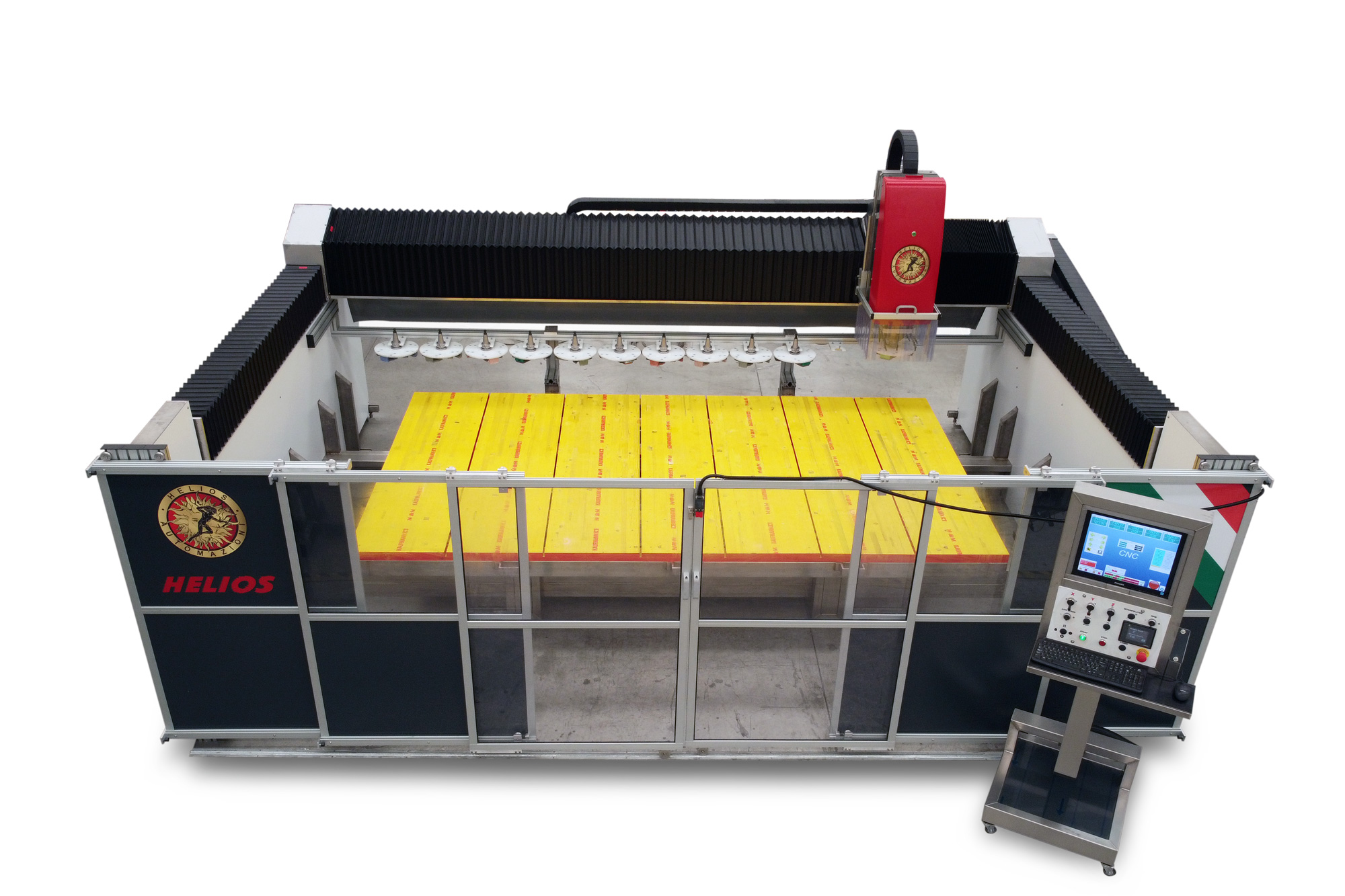

Thanks to its solid structure, precision mechanics, and to the integrated advanced software, the Helios Lux CNC single-head slab polisher by Helios Automazioni is ideal for high-quality finishes on slabs of different materials. It can work both large slabs and smaller, shapeless pieces. It offers a versatile and reliable solution for several polishing needs of different sectors, from marble and granite processing to the use of synthetic materials. Industry 4.0 certification guarantees a cutting-edge experience, while the 2-year full warranty underlines Helios commitment to product quality and reliability.

• Mirror polished

• Leather finishing

• Satin finitising

• Processing of large slabs or small shapeless pieces of various materials: marble, granite, onyx, quartz, synthetic materials

• The precision of the machine and the total control of movements and pressure allow to process even very fragile and thin slabs

| Stainless steel structure | Stainless steel structure and operator console for high resistance to corrosion |

|---|---|

| Brushless motors | Brushless motors power the electronics, ensuring reliability and durability over the time. |

| Precision mechanics | The precision mechanics of screws and recirculating ball guides offers smooth and accurate movements, for high quality machining. |

| Stainless steel working table | The stainless steel working table guarantees the integrity of the table and a total resistance to the processes stress and to corrosion. |

| Run-Touch software | The integrated Run-Touch software makes the use of the machine simple and programming accessible even to less skilled operators. |

| Industry 4.0 certification | The Industry 4.0 certification underlines the up-to-date technology, which allows advanced connectivity and integration into modern production lines. |

| Full warranty | The full 2-year warranty confirms the Helios commitment to product quality and reliability. |

| Lux | |

|---|---|

| Overall dimensions | 212,59 x 151,57 x H96,46 in |

| Working area | X129,92 - Y78,35 - Z12,80 in |

| Motor power | 7,5 kW |

| Spindle rotation speed | 0 ÷ 2400 rpm |

| Installed power | 12 kW |

| Power supply | 400 Volt (3P + N + GND) 50/60 Hz |

| Max. speed axis X | 1181,10 in/min |

| Max. speed axis Y | 1377,95 in/min |

| Max. speed axis Z | 393,70 in/min |

| Table dimensions | 129,92 x 78,74 in |

| Tool changer | Automatic |

| Tools magazine | 11 positions |

| Tilting table with Easy-load system | PhotoScan system |

| Calibrating |